Executive summary

Industry 4.0 is transforming product and consumer convergence, with manufacturing companies looking for solutions to drive increased capacity, speed and quality. This transformation is happening right now — and picking up pace — accelerated by the growing opportunity and normalization of x-shoring.

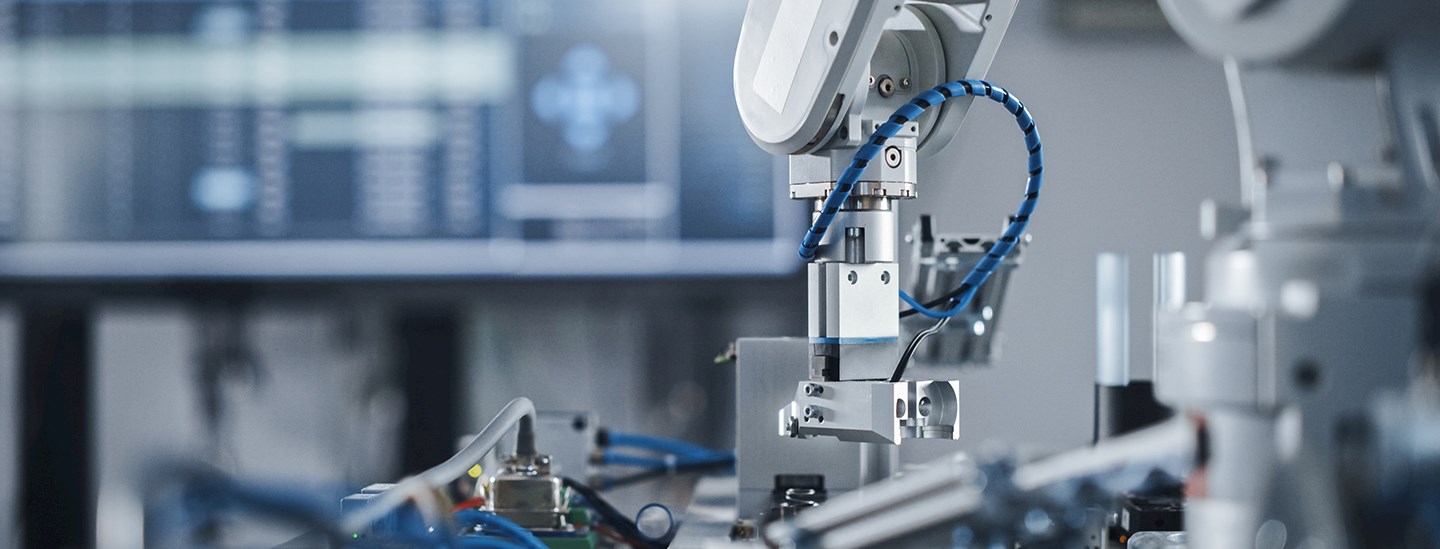

Digitization, AI and integrated tech platforms are streamlining operating processes and connecting transportation, payment and workforce resourcing, creating a new generation of 'smart factories'.

Buoyed by technological advances, spurred into geographical decisions through pandemic experience and geopolitical havoc, what will the manufacturing landscape look like in the near future?

Insights

- Heightened business resilience concerns following the global COVID-19 pandemic have led to a shift in risk tolerance and a drive for increased agility, production efficiency and responsiveness to emerging risks. Manufacturers are re-evaluating supply chains and reshoring operations to adapt to a changing economic reality.

- As inflation, geopolitical tensions and supply chain bottlenecks continue to dampen growth, manufacturers are exploring new opportunities to reduce cost including where Industry 4.0 technologies can help to close the labor price gap. Technology and digitization of production look set to become a game changer for the manufacturing sector, globally.

- Industry 4.0 and investment in IoT and AI led technology to drive efficiency is influencing the trend to re-shore skilled labor and manufacturing operations in highly technologically developed locations.

- In McKinsey's annual survey (2022) tracking the progress of Industry 4.06 within the manufacturing sector, 94% of the respondents said that digital transformation and automated production kept their operations running while 56% said Industry 4.0 technologies had been critical to their COVID-19 crisis response.